Precision Fabrication Machinery Denver Co

The facilities have specialized machine tools, robotic welding, and controlled environments areas. Our team is skilled in all aspects of precision and custom fabrication.

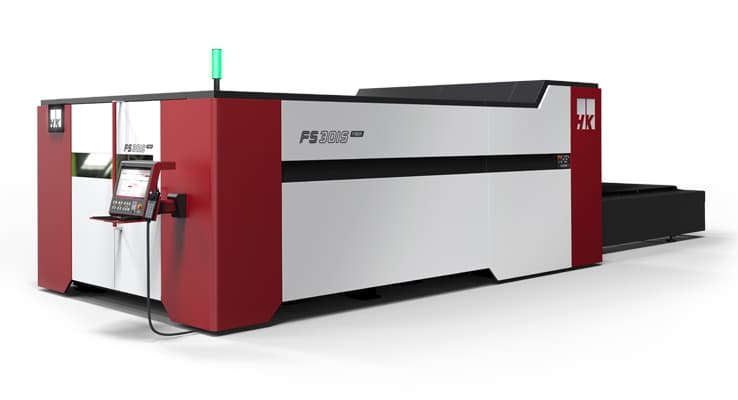

Tube Lasers employs computer-aided modeling software for precise metal fabrication. This intelligent system automates the cutting and finishing of your metals in order to achieve the goal of precise fabrication.